Top quality coating results

Extremely efficient installations

Sustainable relationships

COATIFY

Information and management platform

Access from anywhere and anytime

Industrial companies must constantly improve their productivity, quality and costs This requires accurate production data and continuous monitoring, if possible from any location and at any time.

This is now provided by WAGNER’s new IoT solution. The Internet platform offers clearly visualized master data, real-time productivity monitoring, spare part exchange information and operating instructions with a spare parts list. The data is made available via controllers and sensors of WAGNER products. They are sent over a secure VPN connection to the IoT platform and graphically prepared for display.

Overview of the process

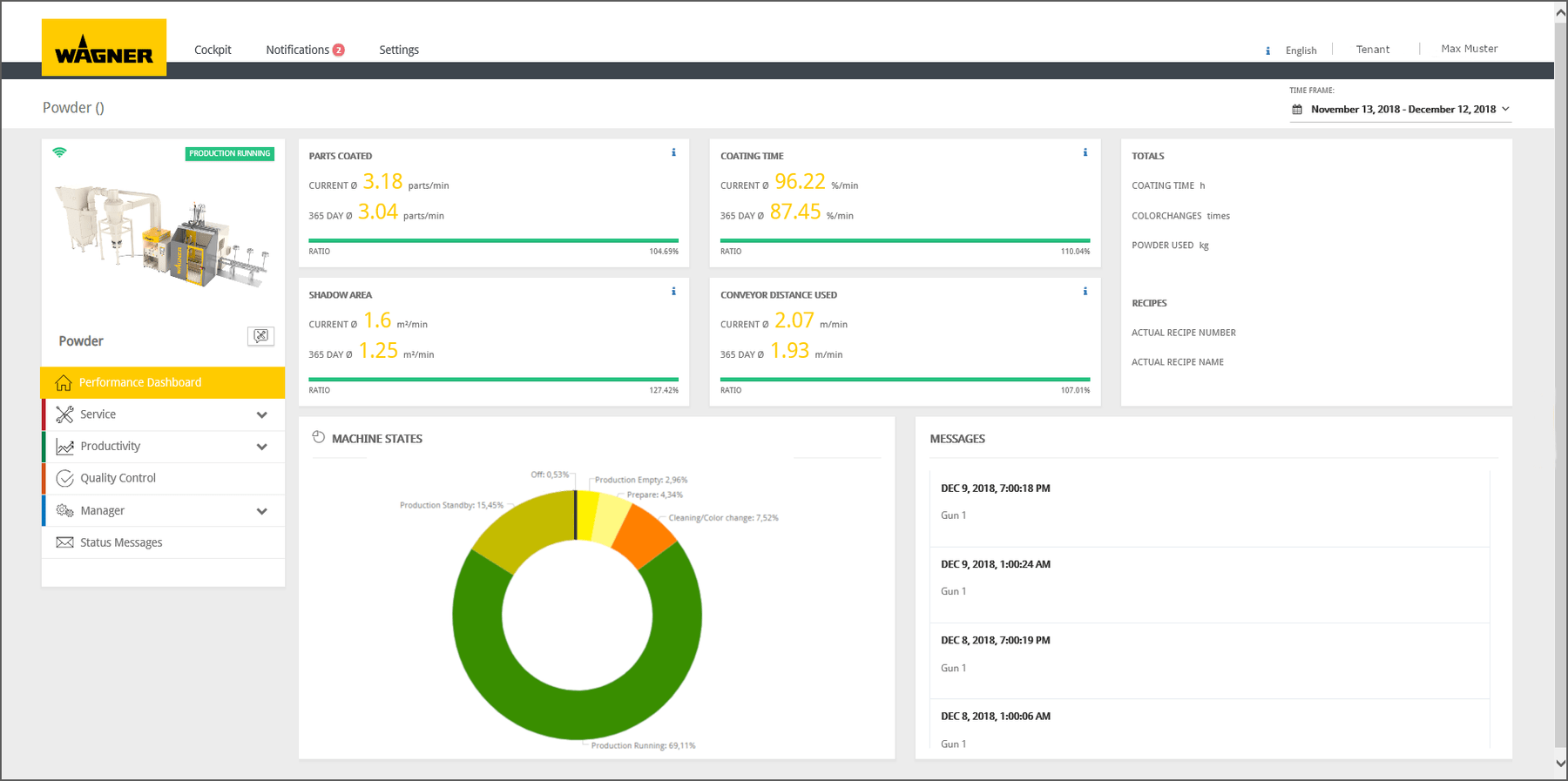

The homepage of the WAGNER IoT platform provides the user with an overview of his powder coating lines and key productivity indicators. This is the starting point for a detailed, visually prepared report. Data such as powder coating time, number of painted pieces or color change times are updated every minute so that live monitoring is possible. Values measured over the last 365 days are used as reference values. The evaluation can be displayed graphically over freely selectable time periods, for example also by shift. Everyone involved in the production process benefits from a high level of transparency and ease of use – from operators to production managers, quality managers and key managers.

Improved productivity

One of the principles of lean management is that only what can be measured can be improved. With the IoT platform, optimization options quickly become clear and the success of the measures taken can be easily controlled. The platform also displays warnings and comments.

WAGNER experts have access to commands via an external function and, if necessary, perform remote maintenance. “For our pilot customers, we expect our solution to increase productivity by up to five percent,” says Mario Oesterle. “These consist of less downtime, better process control with notification function, short response times for less downtime and predictive maintenance measures such as quick replacement of Wear parts.”

Implementation

As a general rule, all WAeGNER lines can be connected to the IoT platform, with an up-to-date programmable controller and associated sensors. “We recommend our solution for new installations or for systems under the age of 5. All other systems can be upgraded,” says Mario Oesterle. Five pilot customers could have tested the platform before it was launched. Returns have always been positive. “What is particularly interesting is that we have access to the platform from any device connected to the Internet, regardless of its location.”

| Perfect process overview |

View the performance data of all coating systems in your company at a glance – on a clear user interface with descriptive diagrams and graphs.

| Secure access from any location |

The controls and sensors in the WAGNER products send data to the platform via a secure VPN connection. The resulting visualized key figures can be displayed on your smartphone, tablet or PC at any time and anywhere.

| Productivity increase up to 5% |

Tight process control, short response times for less downtime and proactive service measures can increase the availability and productivity of your system.

| Reliable reporting function |

In the event of critical events, such as system malfunctions, pending maintenance or if adjustable limits are exceeded or exceeded, you will receive an optional automatic email notification in addition to information via the platform.

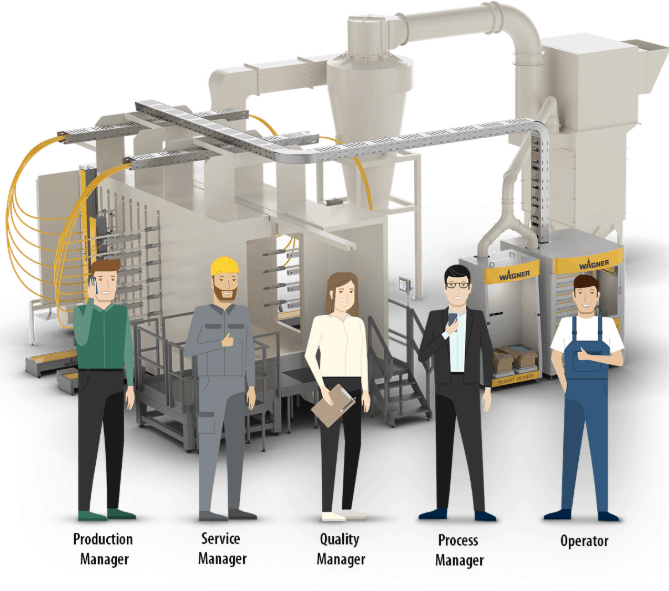

Individual information for each area of responsibility

Production Manager

Service Manager

Quality Manager

Process Manager

Operator

Detailed, clearly structured and attractively presented reports for each integrated system. Current characteristic values such as coating time, number of coated parts or conveyor section can be displayed and compared with historical parameters.

COATIFY.Service

COATIFY.Productivity

COATIFY.Quality Control

COATIFY.Manager

Wagner Landing Page